Compression ignition engines all have one thing in common: high cylinder pressures. These cylinder pressures, and the associated head lift, create a harsh and unforgiving environment for any head gasket. To cope with these stresses, it is essential that a diesel engine head gasket utilizes technologies designed to maximize sealing. Poor head gasket sealing can lead to loss of engine power, overheating, or engine failure. The engineers at Dana created Wave-Stopper™ gaskets to solve real-life, on-the-job problems, so you’ll never have to deal with the frustration and costs associated with a reputation-damaging comeback.

The Victor Reinz® Wave-Stopper feature combats the high combustion pressures commonly found in diesel engines with embossed concentric “waves” that surround the combustion opening. This Dana-patented technology creates a highly uniform seal despite severe service environments. It’s a difference you can see, and it was on display in the Dana Aftermarket booth at the 2019 AAPEX show in Las Vegas. A GM Duramax 6.6-liter diesel engine featuring Wave-Stopper technology served to illustrate how these gaskets solve common problems for customers.

The Victor Reinz® Wave-Stopper feature combats the high combustion pressures commonly found in diesel engines with embossed concentric “waves” that surround the combustion opening. This Dana-patented technology creates a highly uniform seal despite severe service environments. It’s a difference you can see, and it was on display in the Dana Aftermarket booth at the 2019 AAPEX show in Las Vegas. A GM Duramax 6.6-liter diesel engine featuring Wave-Stopper technology served to illustrate how these gaskets solve common problems for customers.

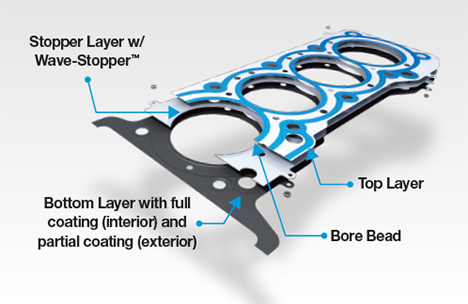

Dana Senior Account Manager Ron Rotunno described the Wave-Stopper feature as a series of concentric emboss beads that surround the combustion opening of the gasket. The Wave-Stopper feature is designed to prevent the over-compression of the gasket’s bore bead, leading to extended gasket life. The innovative Wave-Stopper design “also gives us the capability to vary the bead height, something we call topography,” Rotunno explained, “so bolt load can be moved to areas where it’s needed the most,” such as between bolt spans. The topography within these gaskets allows for uniform sealing stress at the combustion opening.

“All things being equal, less gasket-related bore distortion is the result. As we know, the less bore distortion you have, the better the piston ring seal. The result is better engine performance. When you combine the Wave-Stopper design feature with the precision bore bead, it’s definitely a ‘belt and suspenders’ approach to sealing,” Rotunno added.

One issue that’s present in any internal combustion engine, but that diesel engines are particularly susceptible to, is head lift. Head lift describes the action of the cylinder head lifting off the deck of the engine block during periods of peak cylinder pressure. While many different factors contribute to head lift, the results can range from overheating due to combustion gasses entering the coolant passages, to head gasket damage or failure. Yet Rotunno specified that “MLS gaskets are able to maintain the contact pressure required to seal between the head and the block,” or what’s called “recovery” in the sealing business.

One issue that’s present in any internal combustion engine, but that diesel engines are particularly susceptible to, is head lift. Head lift describes the action of the cylinder head lifting off the deck of the engine block during periods of peak cylinder pressure. While many different factors contribute to head lift, the results can range from overheating due to combustion gasses entering the coolant passages, to head gasket damage or failure. Yet Rotunno specified that “MLS gaskets are able to maintain the contact pressure required to seal between the head and the block,” or what’s called “recovery” in the sealing business.

MLS, or multi-layer steel, gaskets feature multiple layers of embossed steel with a rubber coating. The embossed layers act as a spring that expands to provide contact pressure between the head and the block, thereby maintaining the seal. Wave-Stopper MLS gaskets are engineered at an OE level from the highest-quality materials, such as full hard stainless steel and premium FKM coatings, to meet the demanding sealing requirements of head gaskets in both light and commercial diesel engine vehicles.

Get in touch with a Dana Aftermarket representative today to find out how you can benefit from the pioneering design of Victor Reinz® MLS Wave-Stopper gaskets, or for more on problem-solving innovations from Dana, visit www.SpicerParts.com.